Mechanical Liaison Officer's Report - HEP (5/27/1993)

- aaprcosocialmedia

- Aug 24, 2024

- 19 min read

Subject: HEP (5/27/1993)

[1/3/86] Electrical Consumption - Amtrak has experienced difficulty with some private cars which seem to suck up electrical power after HEP has been installed. It is likely that Amtrak will impose an 85 KW limit per private car on power consumption. HEP power requirements limit the length of the train, and PV's will be subject to bumping if the consumption is too high. The current thinking is that this requirement may go into effect late next year.

[1/3/86] HEP - There is some talk at Amtrak of requiring all private cars to have HEP installed down both sides. The current time frame is four years. You need not tap into it, it will strictly be for pass-through purposes. Apparently the thought is that it aids flexibility in making up trains, and may avoid set-outs. I believe this is not warranted or necessary. Nearly all PV's wish to be on the rear and do not want regular passengers walking through at all hours. Further, west of the Mississippi, all trains are Superliner, without transition cars. There are too many situations where private cars need to have their own self-contained power supply, and when they do, HEP is unnecessary and redundant. Further, the fact that you are burning your own power, rather than using HEP, appears to me to be a definite plus, so far as Amtrak's costs are concerned. In any event, you should keep this in the back of your mind.

[2/26/86] HEP Group Price - We had asked Amtrak to provide us with a group price for installing HEP in our members cars at Beech Grove. This would include the complete system for pass through wiring of both HEP and the 27 point connector, as well as the main reservoir charging pipe, but would not include any tap off this wiring for use within the cars. We have been quoted a price of $32,582 per car for labor and materials by Amtrak, and we believe that further negotiations are in order.

[11/5/86] HEP - It was again emphasized that head-end power will be required, and that we are looking at a 3 - 5 year changeover. The Board of Directors passed a resolution urging the members to change over to HEP. It also passed a resolution urging Amtrak not to make HEP mandatory until it is required of all of the carrier railroads as well. Mr. Laird advised that Power Parts now has a kit of parts available.

[3/2/87] Full H.E.P. - We have received word from H. R. Moore, Executive Vice President of Amtrak, that all privately owned passenger cars, operating on Amtrak trains, will be required to have full H.E.P. effective January 1, 1991. We are pleased to have a date certain to work toward. Lest there be no misunderstanding, full H.E.P. means that you will have all of the required 480 pass-through capability, at all four corners. In addition, you will have to have the main reservoir line, and the 27 point communications connectors.

[3/2/87] H.E.P. Connectors - We are advised that effective immediately, all new H.E.P. installations must be rigged, as they are on the Superliner cars. That is, there must be one permanently attached 480 connector at each corner, and the use of the completely removable jumper connectors will be phased out. The reason is to avoid one more connection where there could be potential problems. We are also advised that the main reservoir line may be tapped for use with door closers, and for the water raising system. As many of you know, it is possible to use the old train signal line for the main reservoir pass through line, providing the angle cocks are changed, and providing that the glad hand is changed to a left handed one. All other connections to the prior signal line, are to be removed, or blanked off. We were further advised that the high-pot test for the 480, and other circuits, is no longer favored by Amtrak. Apparently, it was too much strain on the system, and the test itself is somewhat of a safety hazard.

[3/2/87] Amtrak will no longer supply blueprints, text books, specifications, and the like, free. Instead you will be charged a reasonable cost for this material. You should anticipate that the complete specifications for H.E.P. will cost $50.00. Call and ask for prices before you order materials.

[5/11/87] WIRING - I have forgotten to mention that when you rewire your cars, the nature of the wiring you install is of great importance. While it is satisfactory to use solid copper or aluminum wire when wiring your home, it is not satisfactory to use solid wire when you rewire a railroad car, or any other vehicle subject to vibration. Instead, you should use stranded wire, which is less likely to break from fatigue under the constant flexing caused by running your car over the rails. For the same reason, do not use wire nuts either. Sign up for the HEP school, and learn more.

[10/12/87] HEP Power - Mr. Claytor advises that the January 1, 1991 date for the required installation of full HEP pass through is definite, and set in concrete.

[6/20/88] HEP - As you know, the deadline for installing head-in power on private cars is January 1, 1991, less than 2-1/2 years from now. Mr. Claytor has told us that this date is set in stone, and I am beginning to see a few signs that progress is being made toward meeting this goal. We will probably wish to take a survey within the next year, to see how the project is coming along. 4/0 cable is undoubtedly the largest single item expense. Amtrak has approved Exane brand insulated cable, and has also approved the use of Brand Rex cable as well as Hypalon. Hypalon is also known as diesel cable. Another expensive item is the junction boxes, for the 4/0 cables, and for the 27 pin connector lines, all of which must be made of stainless. You may have these boxes fabricated by your local sheet metal works from the prints supplied at the HEP schools, or you may buy ready-made boxes from Power Parts. In addition, Mr. Bruss has approved the use of the stainless boxes made by Hoffman, which are generally available at electric supply houses throughout the United States. The Hoffman stainless boxes come with a blueprint pocket in the lid. If this pocket extends more than 1/4 inch into the box, it should be removed, and fortunately these boxes are made with removable print pockets. However, by the time you buy the insulators, bus bars, and cable grips, and then do all of the hole punching, you will find you have saved very little, if any, over the complete price from Power Parts. Indeed, I have found the Power Parts prices to be very competitive. You should also be aware that if you attempt to purchase the plugs and connectors directly from Pyle National that there is almost no savings in cost, and the lead times for shipment may run 3 or 4 months. The required 480 v. Westinghouse circuit breakers have been superseded by a new Westinghouse designation.

[8/15/88] HEP - A mistake crept into the report concerning 4/0 cable, and more particularly, the brands of cable which are currently acceptable to Amtrak. Attached is a memo just received from Amtrak which explains the three brands of 4/0 cable which they will accept for train line service underneath the car. Also attached is a memo from Bill Farmer concerning a telephone conversation he had with Dick Bruss of Amtrak concerning HEP requirements, and since it contains other, and further, information, a copy of it is also enclosed. Power Parts advises that it will continue to supply the approved HEP kits; but it will no longer supply Brand Rex 4/0 cable, which was not part of the kit. Another reminder: HEP includes not only the 4/0 cables, but also the 27 pin connector lines, as well as the main reservoir line. It is acceptable to convert the signal line to carry the main reservoir line, but note that you must change to an L head glad hand, which is smaller than, and the reverse of the F head brake pipe connector. Also because of the 140 pound pressure, it is required that the main reservoir line angle cock be of the type which bleeds the hose connections between the cars, when it is closed. By the way, the amount of 4/0 cable which is required consists of 12 runs the length of the car, and with a car length of 85 feet, results in a bare minimum of 1020 feet of 4/0 cable, not counting obstructions. Consequently, you would be well advised to measure carefully before you order from your supplier, so that you will not end up 50 or 60 feet short, because 1000 feet clearly will not do the job. Laird advises that the main reservoir line is now needed on private cars on trains 40 and 41, as well as 46 and 47 because the engine is changed from one end of the train to the other during the middle of the trip. I have also received a note from Les Kasten indicating that he believes the ordinary car owner is incapable of doing a correct and safe job of installing 4/0 cable by himself. After having seen several cars have the cable applied, I must agree with Les. In order to do the job properly, you must have welding skills, conduit bending tools, threading equipment, the advice of a competent electrician, and the help of at least two more strong backs. - [begin Amtrak memo]

4/0 TRAINLINE CABLE FOR UNDERCAR USE Selecting electrical wire for a given application is a more complex task than may be immediately apparent. Among items specified include conductor properties, tinning, stranding, strand bundling, insulation materials, temperature rating, thicknesses, number of layers, separators, etc. These and other properties determine how well a cable will perform in the particular application. The 4/0 cable used for the 480 volt undercar trainline system is subjected to a demanding environment, which calls for stringent wire and insulation specifications. For private car use, Amtrak approves the use of the following materials:

TEMP. TRADE MATERIAL RATING SPECIFICATION MANUFACTURER NAME

Cross-linked Polyolefin (XPLE) 110 C Amtrak Q-78-7 SURPRENANT EXANE

Cross-linked Polyolefin (XPLE) 110 C Amtrak Q-78-7 CHAMPLAIN EXAR

Hypalon 90 C AAR-589 VARIOUS

Exane and Exar are now standard for under car train line wire on Amtrak equipment. This material has superior abrasion resistance to as well as a considerably higher temperature rating. Private car owners who expect to run considerable mileage are advised to use XPLE material rather than Hypalon as it has a greater life expectancy on the road, especially under heavy electrical load conditions. Hypalon is a family of insulating compounds, with varying properties, rather than an specific product. For this reason, if Hypalon insulation is selected, care must be taken to ensure it conforms to AAR spec #589. This specification defines not only the properties of the insulation and its dimensions, but also the copper conductor. "Diesel Locomotive" cable is not necessarily per the AAR spec, and could be very inadequate for railcar service in areas such as insulation thickness, temperature rating, etc.

[end Amtrak memo] [begin Bill Farmer memo]

To: Anyone interested From: Bill Farmer Date: 7/28/88 Subj: Phone conversation with Dick Bruss re HEP requirements

ACCEPTABLE TYPES OF CABLE:

Surprenant Exane is OK for all uses. Exane is superior insulation due to its 110 degree C temperature rating.

Champlain Cable Co. (formerly Haveg Industries) Exar is OK for all uses.

Hypalon is acceptable for all uses PROVIDED it meets AAR spec 589. Hypalon is a DuPont name for the type of insulation. Some Hypalon cable meets AAR 589 and some does not. The user would have to prove the cable used meets this spec. This is a 90 degree C insulation and if operated under full load in Amtrak service, it would be running at its temperature limit. Therefore it would not last as long in this service.

Brand Rex Polyrad XT is not acceptable for the 4/O cable used under the car. It is acceptable for use inside the car.

Cable commonly called "Diesel Locomotive Cable" does not necessarily meet AAR spec 589.

For 27-point communications and NU installations, Exane or Exar or Hypalon is preferred. Exane is smaller in diameter and therefore easier to pull.

MAIN CIRCUIT BREAKER

Westinghouse EHB breaker has been superseded by EHD. FB breaker has been superseded by FDB. All four types are acceptable; EHD is a better breaker than EHB. Be sure the breaker has flat terminals; wires must be connected using crimp-on ring-tongue lugs, with lugs bolted to breaker terminals. EHD breakers come this way; EHB do not except by special factory run.

Cable from junction box to breaker must be 1/0 or larger regardless of car load.

CONDUITS

Rigid conduit is required. 27-point communications, 480-volt control wires, and MU must all be in separate conduits. However, they may all three share the same junction boxes provided that each group is separated from the others (on separate terminal strips).

SPLICES

It is permitted but not required to tape the splices of 4/O wire, before applying the protective sleeve.

TRANSFORMERS

There is no list of approved transformers. Keep in mind that air temperature underneath a parked car can easily reach 140 degrees F. Also keep in mind that moisture could enter a transformer that has openings for ventilation.

LATEST REVISIONS

The latest revision of "CRM 79-4 Conversion of Cars to Run With Amtrak Head End Power," commonly known as the "Head End Power Spec," is revision D dated 10/4/87. This entire spec was missing from the book that was given to me at the HEP school in 2/87. Latest revisions of drawings: Drawing No. Title Latest Revision C-05-7171 End of Car Trainline Connector Locations A E-01-1306 480 Volt & 27 Communications Trainline Schematic C C-01-7169 Electrical Schematic M/U Trainline (none) Push Pull for Private Cars

[end Bill Farmer memo]

[9/26/88] Electrical Committee - At the general membership meeting, Ken Izant, Chairman of the Electrical Committee urged members to keep the capability of handling both 480 and 240 volts on their cars. It is not true that 240 has been torn out everywhere, and the capability of both adds to the flexibility of your car in normal operations, and at conventions. He further urged you to bring the necessary standby cords with you, as the association does not have any to spare. Standby plugs are available through Power Parts, and the 60 amp connectors run approximately $150 for the female, and $125 for the male. Because of the shortage of standby connectors, we were forced to have a series of revolving power outages, just like Con Edison.

[1/26/89] HEP - The wiring schematic passed out for the control wires prior to the New Orleans HEP school in 1988 has been superseded. The new print is E-01-1306. It shows 10 control wires running from end to end, 6 active and 4 spares. Dick Bruss recommends running all of them, as it is much easier to do all at one time. The prior wiring is still compatible with the current standard on Amtrak. The new print is available from Amtrak-Engineering.

[1/26/89] HEP Tool - Ken Izant and Vern Pearson had a handy tool in St. Louis for Inserting and removing HEP plugs.

[4/10/89] Head-End Power - The head-end power modifications are still required by January 1, 1991. This means the full 4/0 cable complements, the 27 pin communications connectors, and the main reservoir line pass-through. Inasmuch as the new 40 year inspection will affect approximately 90 cars in the next two years, and will cost in the ballpark $20,000, we have asked for an extension on the mandatory date for HEP (which will cost approximately $25,000). The request is currently in the hands of Vice President Sullivan, and we have had no indication of how it is being received. Obviously, if you have already done your HEP work, you will have to next proceed with the 40 year inspection. On the other hand, if you have done absolutely nothing, you are quickly going to fall behind, or find your car barred from Amtrak service.

[4/10/89] 4/0 Cable Prices - After conducting an extensive nationwide price check, our members Ken Bitten and Jack Deasy advise me the lowest price they were quoted on Amtrak-approved Exane 4/0 wire was $3.57 per foot. The source is B & K Electric, P. 0. Box 117, Livingston, New York 12541. Ken Bitten purchased the 4/0 cable for four cars and the price noted above included shipping charges. Although the price of 4/0 cable fluctuates with the world price of copper, the suppliers quote represents a very competitive bid. If you are interested in a current price quote, contact Bob Moore at B & K Electric at 518/851-7666.

[6/26/89] HEP Deadline - As you know, the current HEP deadline is January 1, 1991. We have submitted a request to Amtrak seeking an extension of this timetable, because of the truck rebuild requirement. Mr. Burk has recommended a three year extension, and the matter is now lying on Mr. Sullivan's desk for decision.

[6/26/89] HEP Plug Positioning - Les Kasten advises that Amtrak is enforcing its specifications concerning the placement of the HEP plugs and receptacles. The tolerances which are published with the HEP materials are not overly lenient, and Amtrak is apparently rejecting cars which do not meet the tolerances given.

[12/26/89] The deadline for installation of complete head end power remains January, 1991. I had mentioned in my last bulletin that we had requested an extension from Amtrak, but as you were advised at the convention, Mr. D. F. Sullivan, Executive Vice President, wrote us on July 19, 1989 and advised that the deadline will not be changed.

[7/10/90] Head-End Power - The requirement for full HEP goes into effect January 1, 1991. This includes main reservoir pass-through lines and 27 pin connectors. I was asked whether Amtrak would move cars one way to a shop, after the deadline, if the car did not already have HEP. I checked with Elton Miller, and he advises that they will probably allow a one-way, one-time move for this purpose. Elton Miller also advises that his records show 84 cars have some version of head-end power in place. Of this number 30 are without the 27 pin connectors according to Amtrak mechanical records.

[10/2/90] HEP - Dick Bruss advises that Amtrak has reexamined the cable from Brand Rex, and will now accept all of their insulation except for the 4/0 cable. This is also being reexamined. The 4/0 cable which is presently acceptable has insulation made by Exane, Exar, and Hypalon AAR-589 diesel cable. No other 4/0 cable is presently acceptable.

[3/11/91] HEP - Elton Miller reports that there are now 90 private cars in full compliance with the HEP program. That is, they have the full 4/0 cable system, main reservoir line, and 27 pin connectors. Bill Farmer noted at the Galveston Convention that 50% of the cars attending had full HEP capability, which was up from the 28% or so at the San Diego convention. The training cars at our convention gave short lectures on HEP, and Dick Bruss spoke at a general mechanical seminar on the same subject. Jack Deasy, Editor of the Eastern Region Newsletter, provided me with an excellent summary of Mr. Bruss' remarks, as well as a list of the most common installation discrepancies which Amtrak has noted during their inspection of private cars. His excellent materials follow:

FROM THE EASTERN REGION NEWSLETTER by Jack Deasy Dick Bruss, an electrical engineer in Amtrak's mechanical department, is their resident expert on HEP and related electrical systems. He made a detailed presentation on these topics. The only 4/0 wire approved by Amtrak is Exane, Exar or AAR-589 specification Hypalon. Exane is the best and most expensive product. Amtrak is now using Exane with double wall insulation rated at 2000 volts. Balancing the loads, within 5%, across all 3 phases is important when using HEP. In response to a statement/question regarding the cost of modifications (such as modifying the coupler carrier iron) required to comply with Amtrak's specifications for placement of HEP receptacles, he indicated they would consider exceptions/waivers on a case by case basis. A letter requesting the exception/waiver, supported by a drawing with appropriate measurements, should be sent to him for review. A member advised Amtrak personnel do not routinely connect the communications jumper between the last Superliner and a PV; Mr. Bruss said he would try to have this corrected since it negates the conductor's call button. Summary of most common HEP installation discrepancies noted by Amtrak during PV inspections (per Dick Bruss technical seminar presentation at AAPRCO convention):

junction boxes have loose bushings. cutout cocks on air hoses interfere with wiring. improper crimps on 4/0 wire - able to pull the wire out of the crimp by hand! clearance over trucks inadequate for curves & switches. wires in contact with diesel exhaust pipe. 4/0 wires in contact with sharp edges fron cut-off brackets. handbrake chain interferes with cables. 4/0 cables tie-wrapped. white plastic tie-wraps, which deteriorate in sunlight, used to secure wire bundles - use non-deteriorating black tie-wraps. improper connection to circuit breaker - 1/0 Exane or equiv. excessive use of liquidtite conduit underneath car - limit use of liquidtite conduit, which does not resist impact damage as well as rigid conduit, underneath car. excessive cutting into center sill, bolsters and other weldments - be sparing when cutting into the car's structure. strain relief nut on 480 volt fixed jumper flange loose - use some loc-tite. 480 volt fixed jumper length incorrect - use proper length to avoid pull-out or crushing on curves/switches. end of car brackets not able to withstand heavy loads - use appropriate construction (3/16" steel) to withstand heavy loads. 4/0 wire installed too low and with sags - remove sags and get it up as high as possible to minimize impact damage, snow/ice buildup in winter and dragging on crossings. 4/0 cable insulation burnt near mounting brackets - weld the mounting brackets before you pull the cables. inadequate wire size between 480 volt juntion box and main breaker - 1/0 minimum acceptable. unacceptable substitute junction box - must be made from non-magnetic stainless steel. receptacles mounted in the wrong place - mount per specifications or have Amtrak (Bruss) approved deviation/waiver.

Other Dick Bruss comments not included in convention article in Volume 1 Issue 3 AAPRCO Eastern Region Newsletter:

for 240 volt and below circuits, use stranded wire and not solid wire. Avoid "household wire" such as Romex. segregate wiring of different voltages in different conduits. avoid BX underneath a car; it can unscrew. liquidtite conduit is permitted, but should be minimized. Rule of thumb - no more than 18" run of liquidtite.

[3/11/91] Via HEP - One of our members asked if the Amtrak and the Via HEP systems were compatible. The plugs are the same, but the two systems are wired differently. Apparently, Via uses two circuits, one on each side of the train, whereas in Amtrak's system all of the cables are manifolded together under each car. Dick Bruss believes there may be some way to arrange the wiring on our cars so that they will work on Via's system. We await his advice. In the meantime, the GO Transit system is not compatible. It utilizes 570 volts with Cannon plugs, and there is no way to mismatch the wiring between the two systems.

[3/11/91] Take Care of No.1 - Nave Fosse, at the recent Board of Directors' Meeting, had a series of photographs showing broken HEP plugs and jumpers, caused by dragging 480 jumpers which were not tied up to the car by the local railroad which switched the car. The answer is simple, you must watch every move made by an inexperienced switch crew, so that you can make certain that your air hose is chained up, and does not catch in a switch frog; that the 480 jumpers are secured, so they do not snag on the rail; that the water fill valve is turned vertically again, so that you will have air pressure on the water system; etc. The fly in the ointment is that you may not be around when the move is being made, or the work is being done. There is no answer, but do try to make things as goof proof as possible, realizing that many railroad switchmen know absolutely nothing about passenger cars.

[5/31/91] SMP for Private Cars 28603 - Elton Miller has now completed his rewrite of this SMP, which governs the inspection and qualification of private cars. The mechanical committee, consisting of Ed Joscelyn, Harold Schroeder, and the undersigned have reviewed the first draft, and have provided our input to Elton Miller. The new SMP contains many corrections and many clarifications, and very little in the way of additional burdens to the private car owner. One new burden is that the inspection charge by Amtrak for HEP acceptance has been changed from one hour to two hours. In addition, cars operating on trains with Superliner equipment must have two 33" 480 volt extension cables supplied by the owner. This is because the length of the cables which reach between heritage cars are not long enough to reach to the differently placed receptacles on Superliners. The truck laterals have been set out with more particularity, especially in terms of tolerances. The biggest plus is that the requirement for changing out, or scrapping wheels during the 40 year inspection has been changed from 1-5/16" to 1-1/16". The Clearance Engineer has not yet seen our comments, hence we do not expect this SMP to be issued for another two or three weeks.

[8/31/92] 480 HEP Connectors - The Eastern Regional Newsletter, edited by Jack Deasy recently included an article by Martin McDonough, our honorary member from the Boston area. The gist of the article was that when your car is being uncoupled from an Amtrak train, you should be on the ground and watching what the brakeman is doing, because he may be too lazy to manually uncouple the 480 connectors, and simply let the train pull the connectors out of the receptacles. This is akin to the problem I mentioned several reports ago wherein the brakeman failed to properly secure Nave Fosse's 480 connectors, and thus they were allowed to drag on the ground, until they finally snagged in a switch fog. However, to me, the most interesting tidbit in Marty's article was that you should carry a hair dryer on your car, so that you can thaw things out. Particularly, it is often necessary to melt the ice and snow out of the end of an HEP connector which has been left hanging upwardly, so that it collects snow and ice. Similarly, he advises that you arrange a bracket (e.g., an open bottom tube) in which to store such connectors so that they always face downwardly, thus being less likely to collect snow and ice. We have a new supplier of HEP connectors and according to their brochure, they make the 480 and 2710 connectors, receptacles, plugs, extenders, etc. to Amtrak and AAR specifications. Dave Murray is the sales manager (formerly with Pyle National) and the company is Clements National Company, 6650 South Narragansett Avenue, Chicago, Illinois 60638, 1 + 800/966-0016.

[8/31/92] HEP Required to Park at Amtrak Stations - Elton Miller has imposed a requirement that only fully compatible HEP equipped cars may be parked at Amtrak stations. The rationale is to protect the investment already made by those persons whose cars are HEP equipped, and to encourage others to do the same. Unfortunately, these rules apparently do not include the carrier railroads, according to an article in the Eastern Regional Newsletter. There has also been editorial comment in that newsletter and the Western Newsletter. In addition, there will be obvious exceptions in many areas of the country, where Amtrak is merely a tenant, and does not own either the business car track, nor other tracks in the vicinity of the station. For example, in Savannah, the house track is owned by CSX, and is not controlled by Amtrak. In Houston, the business car track is owned by the SP, and not controlled by Amtrak. I am certain the situation is much the same around the rest of the country. The issue should be discussed at the next board meeting.

[5/27/93] HEP Safety Disabled - I don't remember whether or not I have reported this earlier, but when certain of the Amtrak locomotives exceed 30 miles an hours, the HEP train line complete circuit is automatically disabled. This means that a 480 volt HEP conductor can be dragging on the ground, and still be hot. Thus, you should never assume that just because an HEP plug is pulled loose that there is not 480 volts running through the wires.

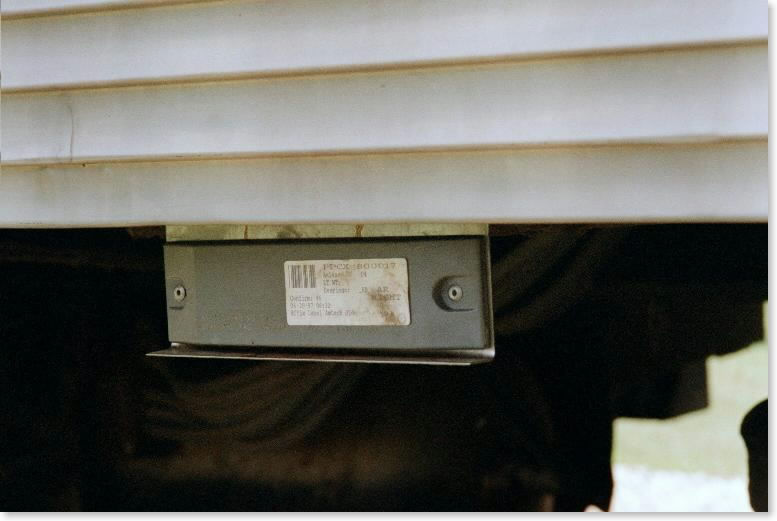

[5/27/93] Theft at LAUPT - In January 1992 I visited the Los Angeles Union Passenger Terminal, and Bill Farmer, who was showing me around, advised that Amtrak had had a number of thefts on the property, particularly of standby cables. I am now advised that the thieves at LAUPT have gotten even bolder. Armed with bolt cutters, they now are stripping the 4/0 copper cable from underneath private cars which are parked at the station. Three have been hit so far. You should be aware, and perhaps we should do as the State Department does, and issue warnings to private car owners as to what stations to avoid. You might also wish to write your congress persons who confirm and pay the salaries of federal judges who invent civil rights for bums and thieves.

Paul L. DeVerter II

Comments