Mechanical Liaison Officer's Report - Wheels - Tread-braked, straight plate, rim stamped (6/16/00)

- aaprcosocialmedia

- Aug 24, 2024

- 3 min read

Subject: Wheels - Tread-braked, straight plate, rim stamped (6/16/00)

Approximately, 5 years ago, the National Transportation Safety Board recommended to the AAR, Amtrak, AAPRCO, and several other organizations that the above identified wheels be immediately taken out of service. (See the prior articles on this subject for the background). We were able to prevail on Amtrak to suggest an alternative, in view of the expense and safety record which we enjoyed. That alternative was to clean the rims, and perform a dye check for cracks at the time of each annual inspection. This was accepted by the NTSB as an acceptable alternative action. There were a couple of conditions, imposed by Amtrak and the NTSB. First, the extension was for 5 years, or until June 2000. Second, the subject wheels could not be mounted on the car if they were not currently under the car.

Notice that there are three conditions which define the subject wheels. All three must be met. The NTSB report has nothing to do with disk-braked wheels. Nonetheless, in a letter from Geo. Binns of Amtrak, an inventory of all rim-stamped wheels was requested. Currently rim-stamped disk-braked wheels are acceptable to Amtrak.

The earlier articles show how to test to see whether the wheels are straight-plate. However, five years ago there were no curved-plate passenger car wheels being made. I understand that some may be being made today. Freight car wheels are currently curved-plate. Currently all new wheels made in the US are believed to be hub-stamped, with the exception of those used on Metro in Washington, DC, who continues to use rim-stamped wheels. Be sure to check before buying foreign made wheels, e.g. from Brazil.

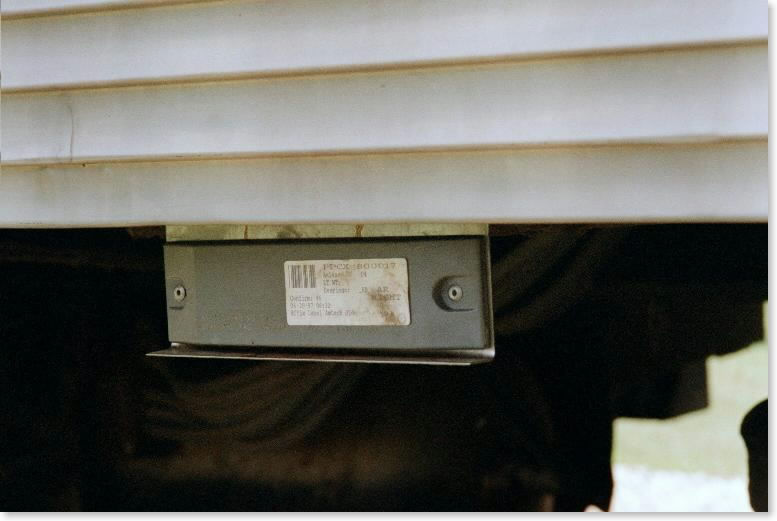

We have been seeking an extension of the current practice. Amtrak has agreed to a two year extension for the subject wheels, but has added two new conditions. We were unable to obtain any relief from these new conditions, which I feel are not justified. They are: the minimum wheel rim thickness for the subject wheels is now one and one/half inches (the AAR standard is one inch and the Amtrak standard for its own cars, but excluding PV's is one and one/quarter inches); and the dye check test must be made before every trip. A memo to this effect was issued by Harold Weisinger on June 8, 2000. I understand that you should check with Harold to see who he will accept as competent to make the dye penetrate test. I imagine it will be required that the person doing so be knowledgeable in such testing. This is a test regularly done by pipeline and other industry welders.

The FRA has decreed that you may not replace any currently in service tread-braked wheels with straight-plate, tread-braked, rim-stamped wheel sets on private cars. The FRA does not address increased thickness nor dye checking for cracks. Thus, you must use hub-stamped wheels as replacements, or else run your car on a railroad not subject to Amtrak rules, or exempt from the FRA rules. Amtrak may make more stringent rules than those required by the FRA if it chooses to, and this is what it has done.

So what do you do with your old subject wheels? There is no prohibition for their use by tourist railways not connected to the general railroad system, or in Mexico or Canada, that I know of. They also make fine door stops.

Paul L. DeVerter II

Comments